Fried Type Kurkures Making Machine

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.The cutting knives can cut into required lengths. The Kurkure/Cheetos are fried in cooking oil or toasted in oven and then cooled before flavoring. Seasoning is sprayed on the surface to achieve different favorable tastes. Due to the delicious flavors and nutrition, it is quite popular with consumers.

Fried Type Kurkures Making Machine

Extruder corn Kurkure nik naks snacks machine is characterized by unique technique, rational configuration, high automation and stable performance. Due to the delicious flavors and nutrition, kurkure cheetos nik naks is quite popular with consumers.After fried and flavored, the final cheetos or kurkure will be more tasty and crispy.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| DLG76 | 75KW | 55KW | 100-120kg/h | 20x 2.0 x 3.0 | 150m³ | 2 | 30 |

| DLG76-II | 140KW | 98KW | 200-240kg/h | 28x 2.0 x 3.0 | 150m³ | 2 | 30 |

| DLG76-III | 205KW | 140KW | 300-360kg/h | 35x 2.0 x 3.0 | 200m³ | 3 | 40 |

| DLG76-IV | 260KW | 180KW | 400-480kg/h | 40x 2.0 x 3.0 | 200m³ | 4 | 50 |

1. Raw materials: Corn Grits

2. Products: Kurkure/Cheetos/Nik Nak with Different Tastes

3. Capacity: 120-480KG/H

4. Flow Chart: Mixing—Extrusion—Separating—Frying/Baking— Flavoring system--Packing

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

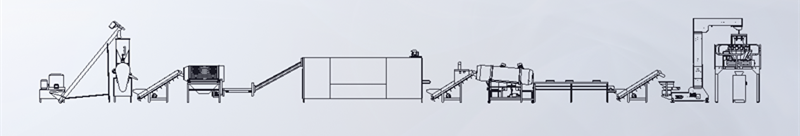

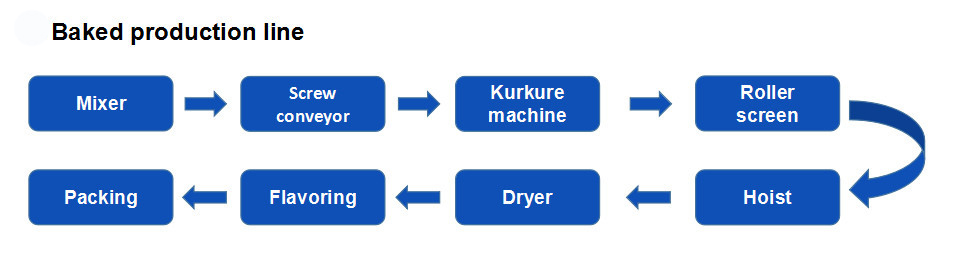

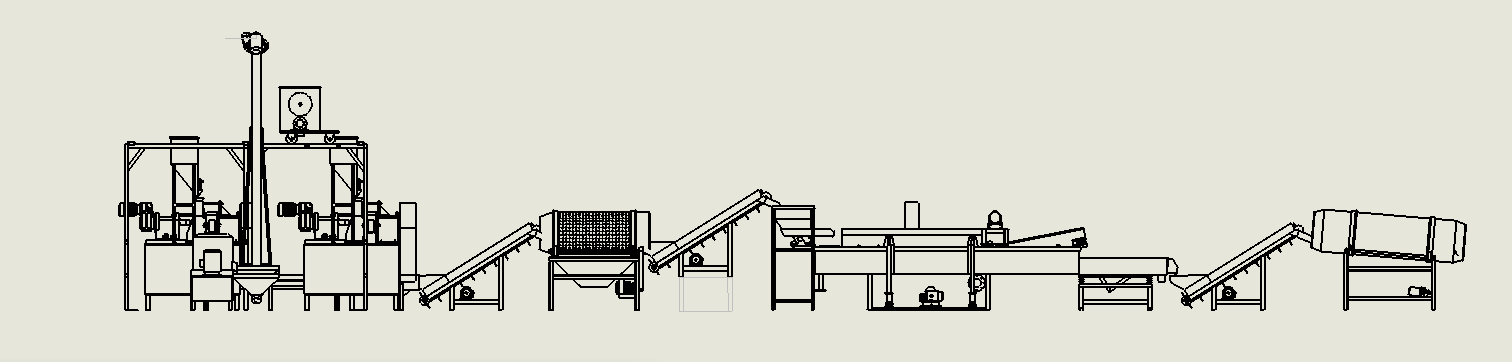

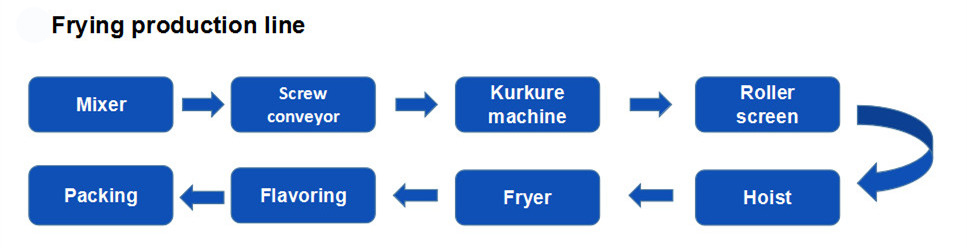

FLOW CHART

Mixing—Extrusion—Separating—Frying/Baking— Flavoring system--Packing

SAMPLES

SERVICE

Pre-sale services

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.